What was the make-or-break moment you had to conquer?

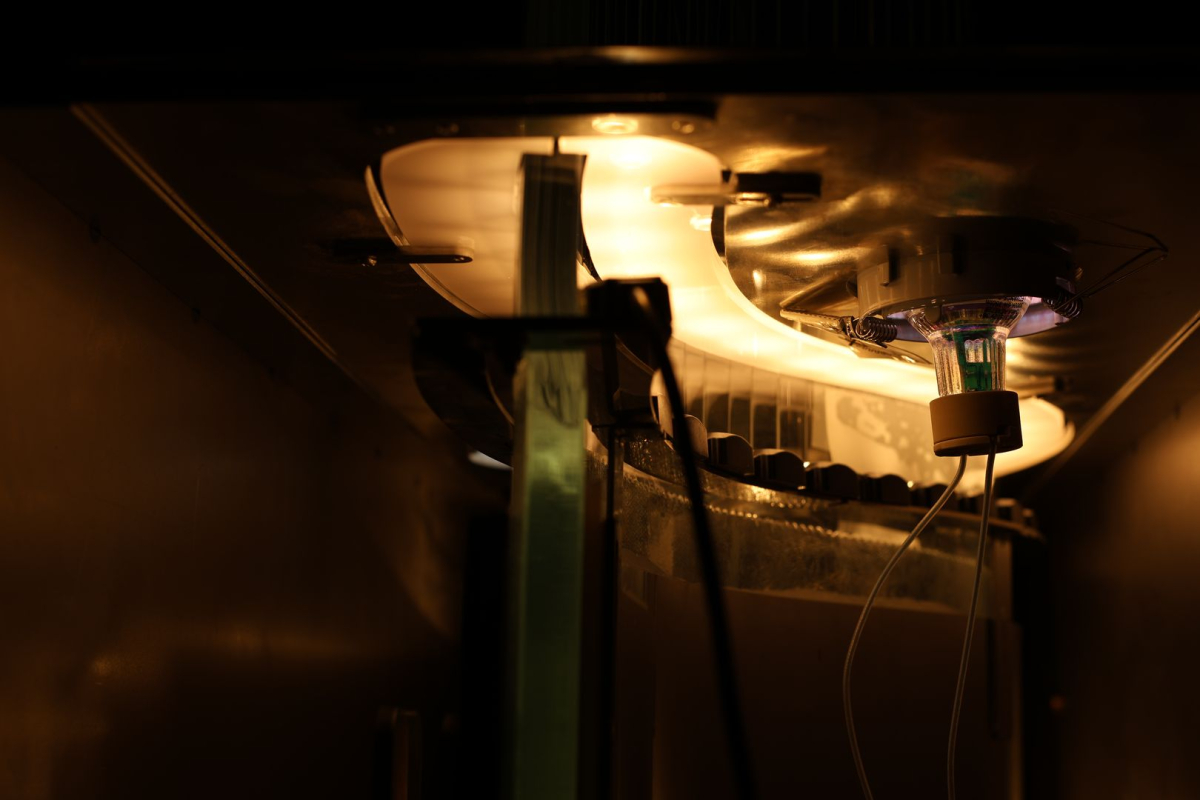

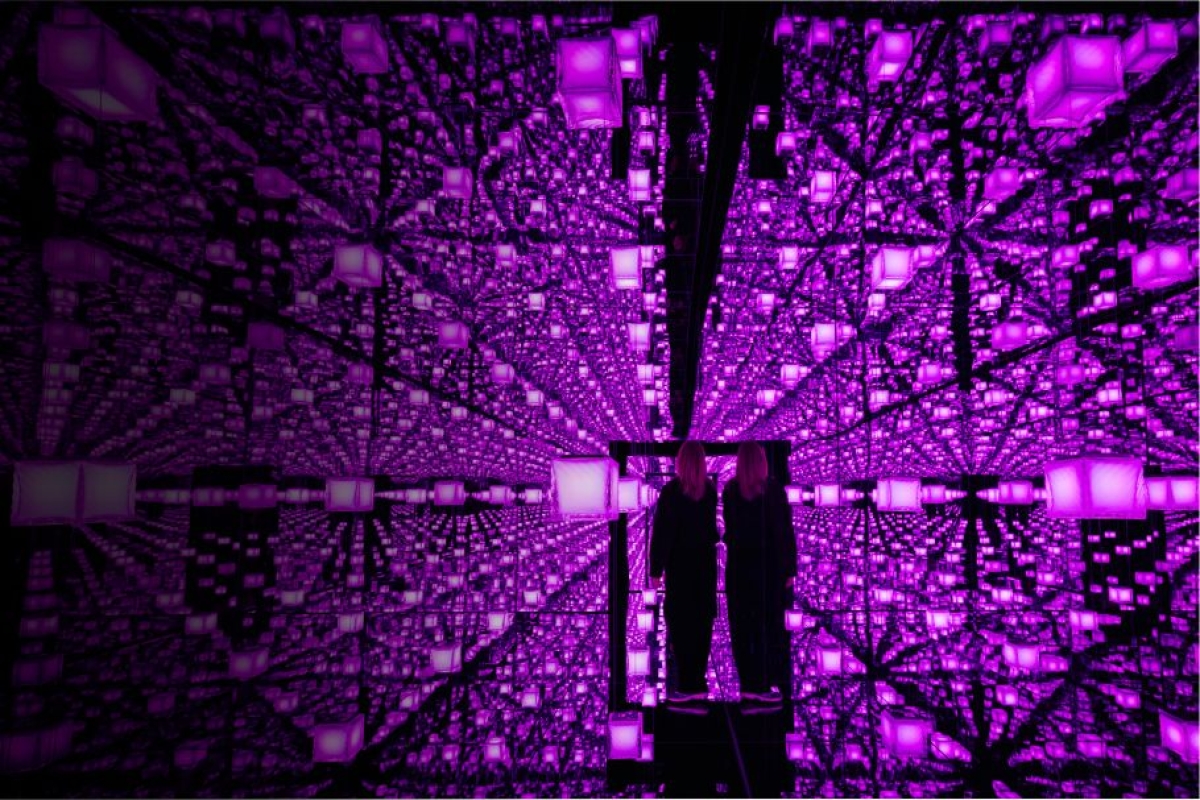

JB: The biggest challenge was the timeline. Every phase had to be precisely coordinated—there was zero room for error. On top of that, the quality had to be flawless. Guests can touch the glass waves, so even the smallest imperfection would stand out. Safety and the complexity of anchoring such large glass pieces were also major hurdles.

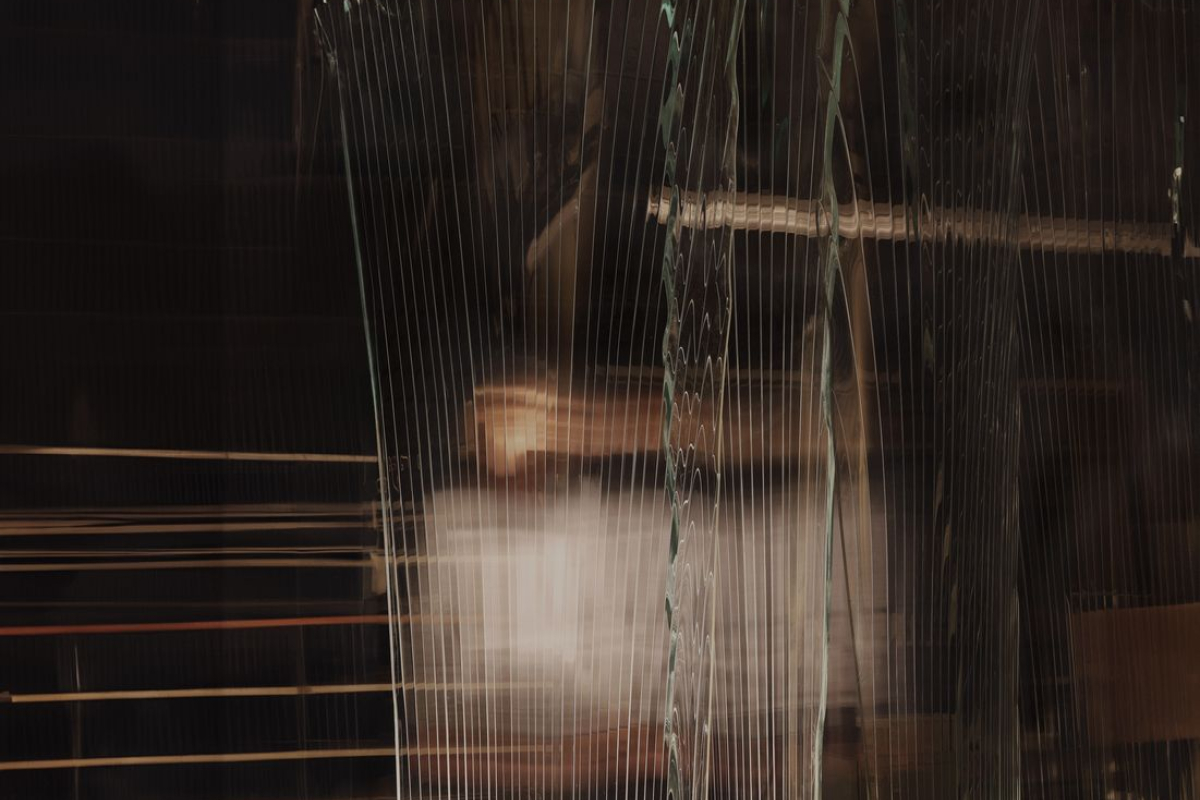

VH: To stay on schedule, we made a bold move—combining the curve shaping and decorative finishing into one production cycle. It had worked for smaller pieces, but scaling it up was risky. The glass needed to be crystal clear, free of pressure marks. There was no margin for imperfection.

What technical or production boundaries did you have to push? What made this project truly innovative?

JB: This project took us into new territory. The key was flexibility—our team adapted quickly, solving challenges as they came. What made Caesars truly special was the close collaboration with the client. Weekly check-ins kept everything aligned and showed just how much the project mattered.

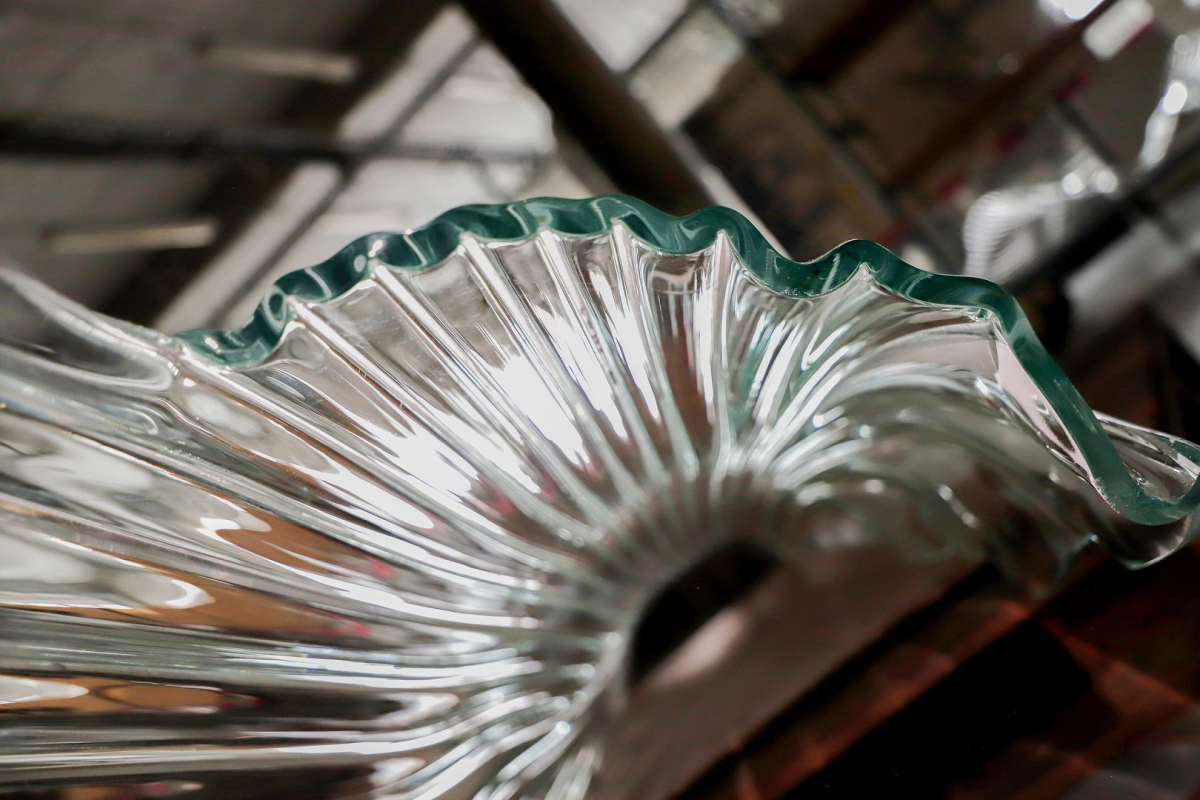

VH: We didn’t just stretch the limits—we redefined them. We had to rethink structural design, material behaviour, and execution from the ground up. Custom moulds were developed to shape the glass waves with exacting precision, preserving both clarity and sculptural elegance.

We also introduced a new coating technique to enhance transparency and eliminate even the tiniest surface flaws. It took extensive testing to get it right. And since each wave came out of the kiln with slight variations, every piece had to be custom-fitted with its own mount and cover—like tailoring a suit. It was precision work that had to appear effortless once installed. This wasn’t just production—it was adaptive craftsmanship.

Looking back, what makes you proudest?

JB: The tight schedule was a real risk, but we pulled it off. The client's satisfaction made it all worthwhile.

VH: A project of this scale demands more than technical skill—it requires an exceptional team. I'm proud to work with people who consistently rise to the occasion and deliver.